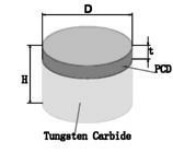

PDC Cutter (Polycrystalline Diamond Compact ) is composed of polycrystalline diamond(PCD) and cemented carbide substrate, which is a kind of super-hard composite produced under ultra-high pressure and ultra-high temperature. It integrates the advantages of diamond and tungsten carbide.

Main Feature:

1. Excellent wear ability and impact resistance

2. Long useful life, high efficiency, and good cost performance

3. The useful life of the PDC bit is 4~5 times that of the diamond bit, 10 times that of the tungsten carbide bit

Application:

PDC cutter(Polycrystalline Diamond Compact) is widely used for making tools applied in the fields of oil and gas drilling, geology exploring, coalfield mining, and the mechanical processing industry.

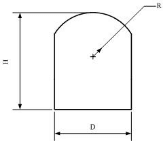

1, Standard:

Standard PDC adopts a new flat, slotted junction plane, the thickness of the diamond layer is from 0.8-2.5mm according to the client’s requirement. They are widely used for Engineering and geological purposes.

| specification | R1919 | R1916 | R1913 | R1619 | R1616 | R1613 | R1313 | R1308 | R1008 | R0808 | R0803 |

| D(mm) | 19.05 | 19.05 | 16.00 | 16.00 | 16.00 | 16.00 | 13.44 | 13.00 | 10.00 | 8.00 | 8.00 |

| H(mm) | 19.00 | 16.31 | 13.20 | 19.00 | 16.31 | 13.20 | 13.20 | 8.00 | 8.00 | 8.00 | 3.53 |

2, Sphere shape:

Sphere-shaped PDC has more excellent shock-resistance toughness (ballistic work is equal to that of hard alloy) and it can be applied to percussion drilling, medium and small drill bits, oil roller bits, down-the-hole drill bits geothermal drilling, etc.

| specification | Q1114 | Q1308 | Q1313 |

|

| D(mm) | 11.10±0.1 | 13.44±0.1 | 13.44±0.1 | |

| H(mm) | 14.30±0.1 | 8.00±0.1 | 13.20±0.1 | |

| R(mm) | 5.76 | 16.00 | 16.00 |

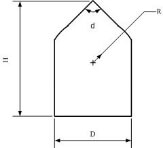

blunt conical-ended shape insert:

| specification | Z1116 | Z1119 | Z1217 |

|

| D(mm) | 11.60±0.1 | 11.60±0.1 | 12.10±0.1 | |

| H(mm) | 16.00±0.1 | 19.10±0.1 | 17.00±0.1 | |

| R(mm) | 4.00 | 4.20 | 4.50 | |

| d | 60º | 56º | 54º |

3, Special Shaped PDC

We could provide specially shaped PDC according to the client’s requirement, including Rectangular shapes, Triangle shapes, Big Diameters,s and other shapes, etc.

Sizes are upon the client’s requirements!

Parameter:

| Name | Application | Code |

| Round PDC | For Oil/Gas field drilling and Geological, Coalfield, Stone processing |

0808 |

| 1004 | ||

| 1008 | ||

| 1204 | ||

| 1304 | ||

| 1308 | ||

| 1313 | ||

| 1608 | ||

| 1613 | ||

| 1616 | ||

| 1908 | ||

| 1913 | ||

| 1916 | ||

| 1919 | ||

| Square PDC | For Geological, Coalfield, Stone processing |

9.4×9.4×8.0 |

| 12.7×12.7×8.0 | ||

| 12x12x4.5 | ||

| Spherical PDC | For core bits and other uncertain industry |

1114 |

| 1117 | ||

| 1210 | ||

| 1218 | ||

| 1308 | ||

| 1420 | ||

| 1620 | ||

| 1624 |